PDF Publication Title:

Text from PDF Page: 016

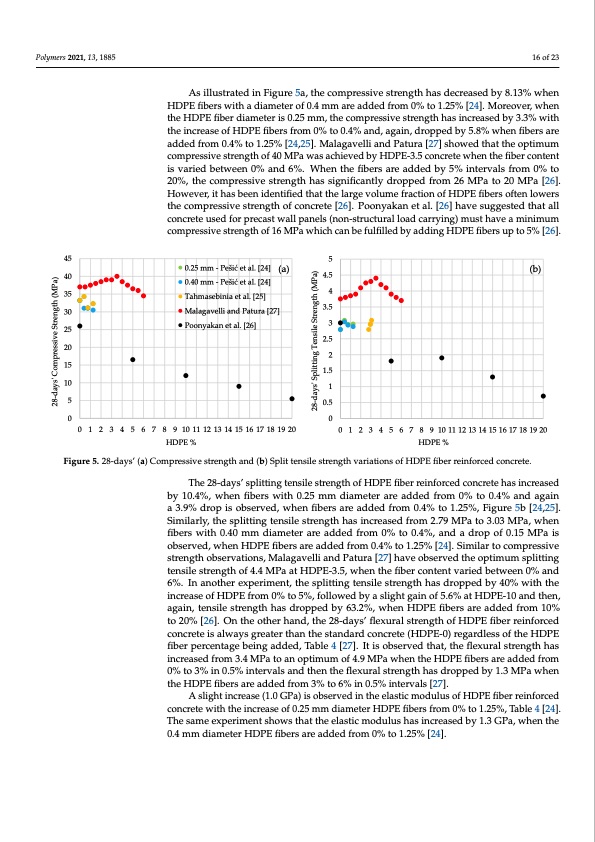

kg kg [26]30.12kg- -150.42-60.2416.570.55- 9 - - 1.3 - - - - - - kg kg [26]30.12kg - - 20 0.56 - 60.2418.07 0.6 - 5.5 - - 0.7 - - - - 1800 48 kg kg Poly[m26e]rs3200.1221,k1g3, 18-85 - 30 0.84 - 60.24 18.07 0.6 - - - - - - - - - 1677 162o0f 23 kg kg As illustrated in Figure 5a, the compressive strength has decreased by 8.13% when As illustrated in Figure 5a, the compressive strength has decreased by 8.13% when HDPE fibers with a diameter of 0.4 mm are added from 0% to 1.25% [24]. Moreover, when HDPE fibers with a diameter of 0.4 mm are added from 0% to 1.25% [24]. Moreover, when the HDPE fiber diameter is 0.25 mm, the compressive strength has increased by 3.3% with the HDPE fiber diameter is 0.25 mm, the compressive strength has increased by 3.3% with the increase of HDPE fibers from 0% to 0.4% and, again, dropped by 5.8% when fibers are the increase of HDPE fibers from 0% to 0.4% and, again, dropped by 5.8% when fibers are added from 0.4% to 1.25% [24,25]. Malagavelli and Patura [27] showed that the optimum added from 0.4% to 1.25% [24,25]. Malagavelli and Patura [27] showed that the optimum compressive strength of 40 MPa was achieved by HDPE-3.5 concrete when the fiber con- compressive strength of 40 MPa was achieved by HDPE-3.5 concrete when the fiber content tent is varied between 0% and 6%. When the fibers are added by 5% intervals from 0% to is varied between 0% and 6%. When the fibers are added by 5% intervals from 0% to 20%, the compressive strength has significantly dropped from 26 MPa to 20 MPa [26]. 20%, the compressive strength has significantly dropped from 26 MPa to 20 MPa [26]. However, it has been identified that the large volume fraction of HDPE fibers often lowers However, it has been identified that the large volume fraction of HDPE fibers often lowers the compressive strength of concrete [26]. Poonyakan et al. [26] have suggested that all the compressive strength of concrete [26]. Poonyakan et al. [26] have suggested that all concrete used for precast wall panels (non-structural load carrying) must have a minimum concrete used for precast wall panels (non-structural load carrying) must have a minimum compressive strength of 16 MPa which can be fulfilled by adding HDPE fibers up to 5% compressive strength of 16 MPa which can be fulfilled by adding HDPE fibers up to 5% [26]. [26]. 45 40 35 30 25 20 15 10 5 0 0 1 2 3 4 5 6 7 8 9 1011121314151617181920 HDPE % 0.25 m 0.40 m m - Pešić m - Pešić Tahmasebinia et al. [25] Malagavelli and Patura [ Poonyakan et al. [26] et al. [24] (a) et al. [24] 27] 5 4.5 4 3.5 3 2.5 2 1.5 1 0.5 0 (b) 0 1 2 3 4 5 6 7 8 9 1011121314151617181920 HDPE % Figure 5. 28-days’ (a) Compressive strength and (b) Split tensile strength variations of HDPE fiber reinforced concrete. Figure 5. 28-days’ (a) Compressive strength and (b) Split tensile strength variations of HDPE fiber reinforced concrete. The 28-days’ splitting tensile strength of HDPE fiber reinforced concrete has in- The 28-days’ splitting tensile strength of HDPE fiber reinforced concrete has increased creased by 10.4%, when fibers with 0.25 mm diameter are added from 0% to 0.4% and by 10.4%, when fibers with 0.25 mm diameter are added from 0% to 0.4% and again again a 3.9% drop is observed, when fibers are added from 0.4% to 1.25%, Figure 5b a 3.9% drop is observed, when fibers are added from 0.4% to 1.25%, Figure 5b [24,25]. [24,25]. Similarly, the splitting tensile strength has increased from 2.79 MPa to 3.03 MPa, Similarly, the splitting tensile strength has increased from 2.79 MPa to 3.03 MPa, when when fibers with 0.40 mm diameter are added from 0% to 0.4%, and a drop of 0.15 MPa is fibers with 0.40 mm diameter are added from 0% to 0.4%, and a drop of 0.15 MPa is observed, when HDPE fibers are added from 0.4% to 1.25% [24]. Similar to compressive observed, when HDPE fibers are added from 0.4% to 1.25% [24]. Similar to compressive strength observations, Malagavelli and Patura [27] have observed the optimum splitting strength observations, Malagavelli and Patura [27] have observed the optimum splitting tensile strength of 4.4 MPa at HDPE-3.5, when the fiber content varied between 0% and tensile strength of 4.4 MPa at HDPE-3.5, when the fiber content varied between 0% and 6%. In another experiment, the splitting tensile strength has dropped by 40% with the 6%. In another experiment, the splitting tensile strength has dropped by 40% with the increase of HDPE from 0% to 5%, followed by a slight gain of 5.6% at HDPE-10 and then, increase of HDPE from 0% to 5%, followed by a slight gain of 5.6% at HDPE-10 and then, again, tensile strength has dropped by 63.2%, when HDPE fibers are added from 10% to again, tensile strength has dropped by 63.2%, when HDPE fibers are added from 10% 20% [26]. On the other hand, the 28-days’ flexural strength of HDPE fiber reinforced con- to 20% [26]. On the other hand, the 28-days’ flexural strength of HDPE fiber reinforced crete is always greater than the standard concrete (HDPE-0) regardless of the HDPE fiber concrete is always greater than the standard concrete (HDPE-0) regardless of the HDPE fiber percentage being added, Table 4 [27]. It is observed that, the flexural strength has increased from 3.4 MPa to an optimum of 4.9 MPa when the HDPE fibers are added from 0% to 3% in 0.5% intervals and then the flexural strength has dropped by 1.3 MPa when the HDPE fibers are added from 3% to 6% in 0.5% intervals [27]. A slight increase (1.0 GPa) is observed in the elastic modulus of HDPE fiber reinforced concrete with the increase of 0.25 mm diameter HDPE fibers from 0% to 1.25%, Table 4 [24]. The same experiment shows that the elastic modulus has increased by 1.3 GPa, when the 0.4 mm diameter HDPE fibers are added from 0% to 1.25% [24]. 28-days' Compressive Strength (MPa) 28-days' Splitting Tensile Strength (MPa)PDF Image | Engineering Performance of Concrete Incorporated with Recycled HDPE

PDF Search Title:

Engineering Performance of Concrete Incorporated with Recycled HDPEOriginal File Name Searched:

6b2d9750f7cf13ccb459f476e519aec39ce1.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |