PDF Publication Title:

Text from PDF Page: 014

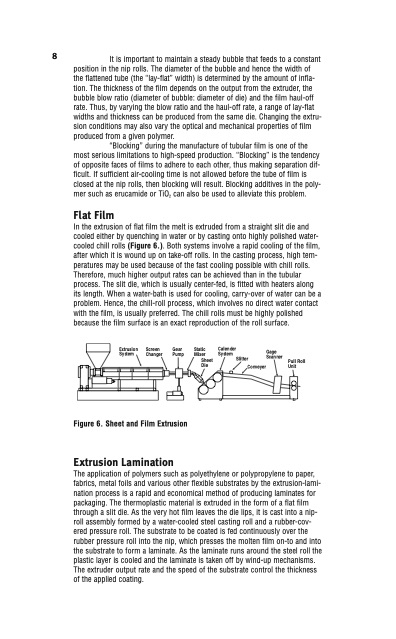

8 It is important to maintain a steady bubble that feeds to a constant position in the nip rolls. The diameter of the bubble and hence the width of the flattened tube (the “lay-flat” width) is determined by the amount of infla- tion. The thickness of the film depends on the output from the extruder, the bubble blow ratio (diameter of bubble: diameter of die) and the film haul-off rate. Thus, by varying the blow ratio and the haul-off rate, a range of lay-flat widths and thickness can be produced from the same die. Changing the extru- sion conditions may also vary the optical and mechanical properties of film produced from a given polymer. “Blocking” during the manufacture of tubular film is one of the most serious limitations to high-speed production. “Blocking” is the tendency of opposite faces of films to adhere to each other, thus making separation dif- ficult. If sufficient air-cooling time is not allowed before the tube of film is closed at the nip rolls, then blocking will result. Blocking additives in the poly- mer such as erucamide or TiO2 can also be used to alleviate this problem. Flat Film In the extrusion of flat film the melt is extruded from a straight slit die and cooled either by quenching in water or by casting onto highly polished water- cooled chill rolls (Figure 6.). Both systems involve a rapid cooling of the film, after which it is wound up on take-off rolls. In the casting process, high tem- peratures may be used because of the fast cooling possible with chill rolls. Therefore, much higher output rates can be achieved than in the tubular process. The slit die, which is usually center-fed, is fitted with heaters along its length. When a water-bath is used for cooling, carry-over of water can be a problem. Hence, the chill-roll process, which involves no direct water contact with the film, is usually preferred. The chill rolls must be highly polished because the film surface is an exact reproduction of the roll surface. Extrusion Screen Gear System Changer Pump Figure 6. Sheet and Film Extrusion Extrusion Lamination Static Mixer Sheet Die Calender Gage System Scanner Conveyer Slitter Pull Roll Unit The application of polymers such as polyethylene or polypropylene to paper, fabrics, metal foils and various other flexible substrates by the extrusion-lami- nation process is a rapid and economical method of producing laminates for packaging. The thermoplastic material is extruded in the form of a flat film through a slit die. As the very hot film leaves the die lips, it is cast into a nip- roll assembly formed by a water-cooled steel casting roll and a rubber-cov- ered pressure roll. The substrate to be coated is fed continuously over the rubber pressure roll into the nip, which presses the molten film on-to and into the substrate to form a laminate. As the laminate runs around the steel roll the plastic layer is cooled and the laminate is taken off by wind-up mechanisms. The extruder output rate and the speed of the substrate control the thickness of the applied coating.PDF Image | Dynisco Extrusion Processors Handbook

PDF Search Title:

Dynisco Extrusion Processors HandbookOriginal File Name Searched:

27429_Legacy_Txt.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |