PDF Publication Title:

Text from PDF Page: 005

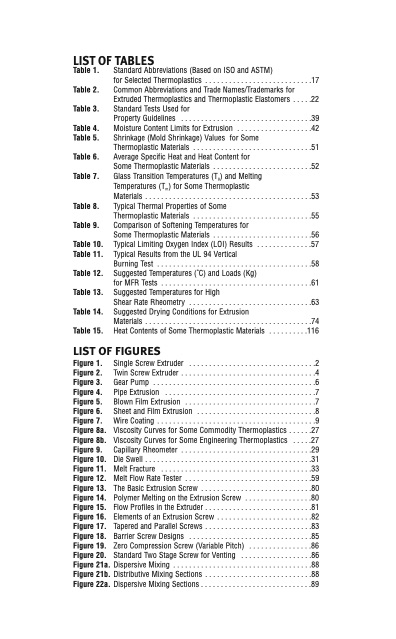

LIST OF TABLES Table 1. Table 2. Table 3. Table 4. Table 5. Table 6. Table 7. Table 8. Table 9. Table 10. Table 11. Table 12. Table 13. Table 14. Table 15. Standard Abbreviations (Based on ISO and ASTM) for Selected Thermoplastics . . . . . . . . . . . . . . . . . . . . . . . Common Abbreviations and Trade Names/Trademarks for Extruded Thermoplastics and Thermoplastic Elastomers . Standard Tests Used for Property Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Moisture Content Limits for Extrusion . . . . . . . ........ Shrinkage (Mold Shrinkage) Values for Some Thermoplastic Materials . . . . . . . . . . . . . . . . . . . . . . . . . . Average Specific Heat and Heat Content for Some Thermoplastic Materials . . . . . . . . . . . . . . . . . . . . . Glass Transition Temperatures (Tg) and Melting Temperatures (Tm) for Some Thermoplastic Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Typical Thermal Properties of Some Thermoplastic Materials . . . . . . . . . . . . . . . . . . . . . . . . . . Comparison of Softening Temperatures for Some Thermoplastic Materials . . . . . . . . . . . . . . . . . . . . . TypicalLimitingOxygenIndex(LOI)Results ..............57 Typical Results from the UL 94 Vertical Burning Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Suggested Temperatures ( ̊C) and Loads (Kg) for MFR Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Suggested Temperatures for High Shear Rate Rheometry . . . . . . . . . . . . . . . . . . . . . . . . . . Suggested Drying Conditions for Extrusion Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Heat Contents of Some Thermoplastic Materials . . . . . . . . . .17 . . . .22 . . . .39 . . . .42 . . . .51 . . . .52 . . . .53 . . . .55 . . . .56 . . . . .58 . . . . .61 . . . . .63 . . . . .74 ....116 Single Screw Extruder .. Twin Screw Extruder . . .. Gear Pump . . . . . . . . . .. Pipe Extrusion . . . . . . .. Blown Film Extrusion . .. Sheet and Film Extrusion Wire Coating . . . . . . . . . . Viscosity Curves for Some Commodity Thermoplastics . Viscosity Curves for Some Engineering Thermoplastics Capillary Rheometer . . . . . . . . . . . . . . . . . . .. . . . . . . . . Die Swell . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . Melt Fracture . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . Melt Flow Rate Tester . . . . . . . . . . . . . . . . . .. . . . . . . . . The Basic Extrusion Screw .............. ........ . PolymerMeltingontheExtrusionScrew .................80 Flow Profiles in the Extruder . . . . . . . . . . . . . . . . . . . . . . . . . . .81 Elements of an Extrusion Screw . . . . . . . . . . . . . . . . . . . . . . . .82 Tapered and Parallel Screws . . . . . . . . . . . . . . . . . . . . . . . . . . .83 Barrier Screw Designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85 ZeroCompressionScrew(VariablePitch) ................86 Standard Two Stage Screw for Venting . . . . . . . . . . . . . . . . . .86 Dispersive Mixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88 Distributive Mixing Sections . . . . . . . . . . . . . . . . . . . . . . . . . . .88 Dispersive Mixing Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . .89 LIST OF FIGURES Figure 1. Figure 2. Figure 3. Figure 4. Figure 5. Figure 6. Figure 7. Figure 8a. Figure 8b. Figure 9. Figure 10. Figure 11. Figure 12. Figure 13. Figure14. Figure 15. Figure 16. Figure 17. Figure 18. Figure19. Figure 20. Figure 21a. Figure 21b. Figure 22a. ............... ........ . . . . . . . . . . . . . . . .. . . . . . . . . . ...................... . . ...................... . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . ...................... . . . . . . .2 . . . . . .4 . . . . . .6 . . . . . .7 . . . . . .7 . . . . . .8 . . . . . .9 .....27 .....27 . . . . .29 . . . . .31 . . . . .33 . . . . .59 . . . . .80PDF Image | Dynisco Extrusion Processors Handbook

PDF Search Title:

Dynisco Extrusion Processors HandbookOriginal File Name Searched:

27429_Legacy_Txt.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |