PDF Publication Title:

Text from PDF Page: 003

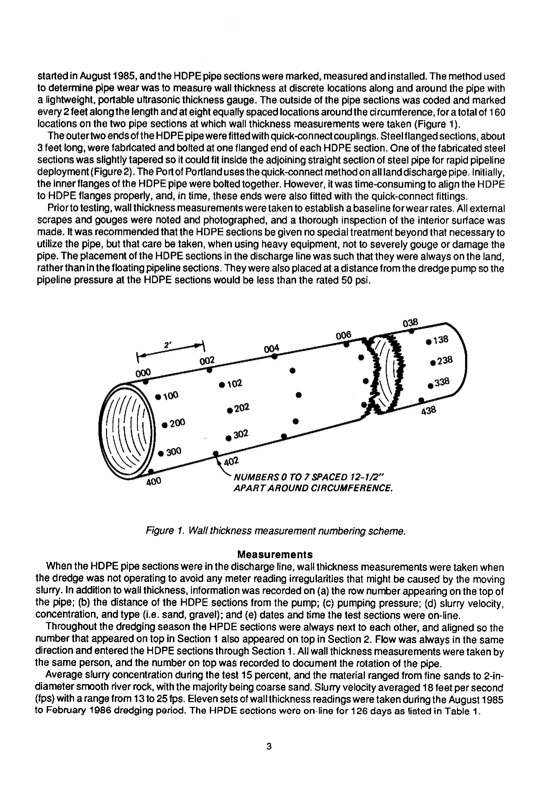

startedin August1985, and the HDPE pipe sections were marked, measured andinstalled. The method used to determine ppe wear was to measure wall thickness at discrete locations along and around the pipe with a lightweight, portable ultrasonic thickness gauge. The outside of the pipe sections was coded and marked every 2 feet along the length and at eight equally spaced locations around the circumference, for a totalof 160 locations on the two pipe sections at which wall thickness measurements were taken Figure 1!, The outer two ends of the HDPE pipe were fitted with quick-connect couplings. Steel flanged sections, about 3 feet long, were fabricated and bolted at one flanged end of each HDPE section. One of the fabricated steel sectionswasslightlytaperedsoitcouldfitinsidetheadjoiningstraightsectionofsteelpipeforrapidpipeline deploymentFigure2!,ThePortofPortlandusesthequick-connecmtethodonalllanddischargepipe.Initially, the inner flanges of the HDPE pipe were bolted together. However, it was time-consuming to align the HDPE to HDPEflangesproperly,and,in time,theseendswerealsofittedwiththequick-connecftittings. Prior to testing, wall thickness measurements were taken to establish a baselinefor wear rates. All external scrapes and gouges were noted and photographed, and a thorough inspection of the interior surface was made. It was recommended that the HDPE sections be given no special treatment beyond that necessary to utilizethepipe,butthatcarebetaken,whenusingheavyequipment,nottoseverelygougeordamagethe pipe, The placement of the HDPE sections in the discharge line was such that they were always on the land, rather than in the floating pipeline sections, They were also placed at a distancefrom the dredge pump so the pipeline pressure at the HOPE sections would be less than the rated 50 psi, APAR T AROUND CIRCUMFERENCE. Figure f. Wall thickness measurement numbering scheme, Measurements Whenthe HDPEpipesectionswerein the dischargeline,wallthicknessmeasurementsweretakenwhen thedredgewasnotoperatingto avoidanymetereadingirregularitiethatmightbecausedbythemoving slurry.InadditiontowaIIthicknessi,nformatiownasrecordedona!therownumbearppearingonthetopof thepipe; b!thedistanceoftheHDPEsectionsfromthepump;c!pumpingpressure;d!slurryvelocity, concentrationa,ndtypei.e.sand,gravel!;ande!datesandtimethetestsectionswereon-line. ThroughouthedredgingseasontheHPDEsectionswerealwaysnextto eachother,andalignedsothe numberthat appearedon top in Section1 alsoappearedon top in Section2. Flowwas alwaysin the same directionandenteredtheHDPEsectionsthroughSection1.Allwallthicknessmeasuremenwtseretakenby the sameperson,and the numberon top was recordedto documentthe rotationof the pipe, Averageslurryconcentrationduringthetest 15percent,andthe materialrangedfromfine sandsto 2-in- diametersmoothriverrock,withthe majoritybeingcoarsesand.Slurryvelocityaveraged18feet per second fps!witha rangefrom13to 25fps.ElevensetsofwallthicknessreadingsweretakenduringtheAugust1985 to February 1986 dredging period. The HPDE sections were on-line for 126 days as listed in Table 1,PDF Image | Dredging Applications of High Density Polyethylene Pipe

PDF Search Title:

Dredging Applications of High Density Polyethylene PipeOriginal File Name Searched:

tamuw86005_part1.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |