PDF Publication Title:

Text from PDF Page: 026

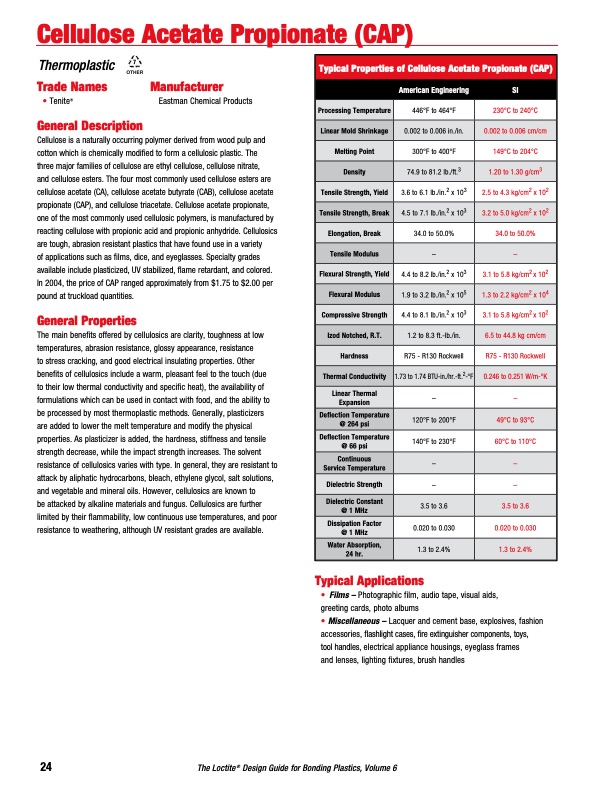

Cellulose Acetate Propionate (CAP) Typical Properties of Cellulose Acetate Propionate (CAP) American Engineering SI Processing Temperature 446°F to 464°F 230°C to 240°C Linear Mold Shrinkage 0.002 to 0.006 in./in. 0.002 to 0.006 cm/cm Melting Point 300°F to 400°F 149°C to 204°C Density 74.9 to 81.2 lb./ft.3 1.20 to 1.30 g/cm3 Tensile Strength, Yield 3.6 to 6.1 lb./in.2 x 103 2.5 to 4.3 kg/cm2 x 102 Tensile Strength, Break 4.5 to 7.1 lb./in.2 x 103 3.2 to 5.0 kg/cm2 x 102 Elongation, Break 34.0 to 50.0% 34.0 to 50.0% Tensile Modulus – – Flexural Strength, Yield 4.4 to 8.2 lb./in.2 x 103 3.1 to 5.8 kg/cm2 x 102 Flexural Modulus 1.9 to 3.2 lb./in.2 x 105 1.3 to 2.2 kg/cm2 x 104 Compressive Strength 4.4 to 8.1 lb./in.2 x 103 3.1 to 5.8 kg/cm2 x 102 Izod Notched, R.T. 1.2 to 8.3 ft.-lb./in. 6.5 to 44.8 kg cm/cm Hardness R75 - R130 Rockwell R75 - R130 Rockwell Thermal Conductivity 1.73 to 1.74 BTU-in./hr.-ft.2-°F 0.246 to 0.251 W/m-°K Linear Thermal Expansion – – Deflection Temperature @ 264 psi 120°F to 200°F 49°C to 93°C Deflection Temperature @ 66 psi 140°F to 230°F 60°C to 110°C Continuous Service Temperature – – Dielectric Strength – – Dielectric Constant @ 1 MHz 3.5 to 3.6 3.5 to 3.6 Dissipation Factor @ 1 MHz 0.020 to 0.030 0.020 to 0.030 Water Absorption, 24 hr. 1.3 to 2.4% 1.3 to 2.4% Thermoplastic Trade Names Manufacturer • Tenite® Eastman Chemical Products General Description Cellulose is a naturally occurring polymer derived from wood pulp and cotton which is chemically modified to form a cellulosic plastic. The three major families of cellulose are ethyl cellulose, cellulose nitrate, and cellulose esters. The four most commonly used cellulose esters are cellulose acetate (CA), cellulose acetate butyrate (CAB), cellulose acetate propionate (CAP), and cellulose triacetate. Cellulose acetate propionate, one of the most commonly used cellulosic polymers, is manufactured by reacting cellulose with propionic acid and propionic anhydride. Cellulosics are tough, abrasion resistant plastics that have found use in a variety of applications such as films, dice, and eyeglasses. Specialty grades available include plasticized, UV stabilized, flame retardant, and colored. In 2004, the price of CAP ranged approximately from $1.75 to $2.00 per pound at truckload quantities. General Properties The main benefits offered by cellulosics are clarity, toughness at low temperatures, abrasion resistance, glossy appearance, resistance to stress cracking, and good electrical insulating properties. Other benefits of cellulosics include a warm, pleasant feel to the touch (due to their low thermal conductivity and specific heat), the availability of formulations which can be used in contact with food, and the ability to be processed by most thermoplastic methods. Generally, plasticizers are added to lower the melt temperature and modify the physical properties. As plasticizer is added, the hardness, stiffness and tensile strength decrease, while the impact strength increases. The solvent resistance of cellulosics varies with type. In general, they are resistant to attack by aliphatic hydrocarbons, bleach, ethylene glycol, salt solutions, and vegetable and mineral oils. However, cellulosics are known to be attacked by alkaline materials and fungus. Cellulosics are further limited by their flammability, low continuous use temperatures, and poor resistance to weathering, although UV resistant grades are available. 24 The Loctite® Design Guide for Bonding Plastics, Volume 6 Typical Applications • Films – Photographic film, audio tape, visual aids, greeting cards, photo albums • Miscellaneous – Lacquer and cement base, explosives, fashion accessories, flashlight cases, fire extinguisher components, toys, tool handles, electrical appliance housings, eyeglass frames and lenses, lighting fixtures, brush handlesPDF Image | Design Guide for Bonding Plastics Volume 6 LT-2197

PDF Search Title:

Design Guide for Bonding Plastics Volume 6 LT-2197Original File Name Searched:

henkel-loctite-design-guide-plastic-bonding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |