PDF Publication Title:

Text from PDF Page: 016

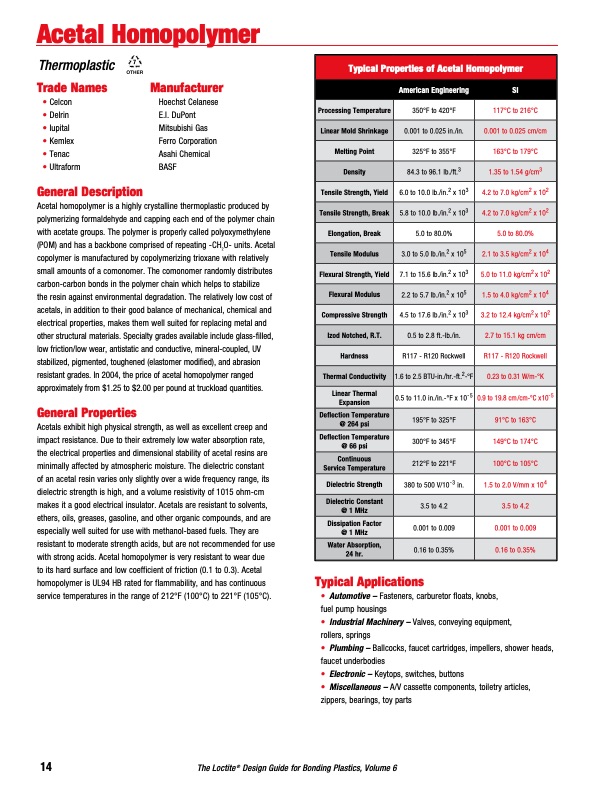

Acetal Homopolymer Typical Properties of Acetal Homopolymer American Engineering SI Processing Temperature 350°F to 420°F 117°C to 216°C Linear Mold Shrinkage 0.001 to 0.025 in./in. 0.001 to 0.025 cm/cm Melting Point 325°F to 355°F 163°C to 179°C Density 84.3 to 96.1 lb./ft.3 1.35 to 1.54 g/cm3 Tensile Strength, Yield 6.0 to 10.0 lb./in.2 x 103 4.2 to 7.0 kg/cm2 x 102 Tensile Strength, Break 5.8 to 10.0 lb./in.2 x 103 4.2 to 7.0 kg/cm2 x 102 Elongation, Break 5.0 to 80.0% 5.0 to 80.0% Tensile Modulus 3.0 to 5.0 lb./in.2 x 105 2.1 to 3.5 kg/cm2 x 104 Flexural Strength, Yield 7.1 to 15.6 lb./in.2 x 103 5.0 to 11.0 kg/cm2 x 102 Flexural Modulus 2.2 to 5.7 lb./in.2 x 105 1.5 to 4.0 kg/cm2 x 104 Compressive Strength 4.5 to 17.6 lb./in.2 x 103 3.2 to 12.4 kg/cm2 x 102 Izod Notched, R.T. 0.5 to 2.8 ft.-lb./in. 2.7 to 15.1 kg cm/cm Hardness R117 - R120 Rockwell R117 - R120 Rockwell Thermal Conductivity 1.6 to 2.5 BTU-in./hr.-ft.2-°F 0.23 to 0.31 W/m-°K Linear Thermal Expansion 0.5 to 11.0 in./in.-°F x 10-5 0.9 to 19.8 cm/cm-°C x10-5 Deflection Temperature @ 264 psi 195°F to 325°F 91°C to 163°C Deflection Temperature @ 66 psi 300°F to 345°F 149°C to 174°C Continuous Service Temperature 212°F to 221°F 100°C to 105°C Dielectric Strength 380 to 500 V/10-3 in. 1.5 to 2.0 V/mm x 104 Dielectric Constant @ 1 MHz 3.5 to 4.2 3.5 to 4.2 Dissipation Factor @ 1 MHz 0.001 to 0.009 0.001 to 0.009 Water Absorption, 24 hr. 0.16 to 0.35% 0.16 to 0.35% Thermoplastic Trade Names • Celcon • Delrin • Iupital • Kemlex • Tenac • Ultraform General Description Manufacturer Hoechst Celanese E.I. DuPont Mitsubishi Gas Ferro Corporation Asahi Chemical BASF Acetal homopolymer is a highly crystalline thermoplastic produced by polymerizing formaldehyde and capping each end of the polymer chain with acetate groups. The polymer is properly called polyoxymethylene (POM) and has a backbone comprised of repeating -CH2O- units. Acetal copolymer is manufactured by copolymerizing trioxane with relatively small amounts of a comonomer. The comonomer randomly distributes carbon-carbon bonds in the polymer chain which helps to stabilize the resin against environmental degradation. The relatively low cost of acetals, in addition to their good balance of mechanical, chemical and electrical properties, makes them well suited for replacing metal and other structural materials. Specialty grades available include glass-filled, low friction/low wear, antistatic and conductive, mineral-coupled, UV stabilized, pigmented, toughened (elastomer modified), and abrasion resistant grades. In 2004, the price of acetal homopolymer ranged approximately from $1.25 to $2.00 per pound at truckload quantities. General Properties Acetals exhibit high physical strength, as well as excellent creep and impact resistance. Due to their extremely low water absorption rate, the electrical properties and dimensional stability of acetal resins are minimally affected by atmospheric moisture. The dielectric constant of an acetal resin varies only slightly over a wide frequency range, its dielectric strength is high, and a volume resistivity of 1015 ohm-cm makes it a good electrical insulator. Acetals are resistant to solvents, ethers, oils, greases, gasoline, and other organic compounds, and are especially well suited for use with methanol-based fuels. They are resistant to moderate strength acids, but are not recommended for use with strong acids. Acetal homopolymer is very resistant to wear due to its hard surface and low coefficient of friction (0.1 to 0.3). Acetal homopolymer is UL94 HB rated for flammability, and has continuous service temperatures in the range of 212°F (100°C) to 221°F (105°C). Typical Applications • Automotive – Fasteners, carburetor floats, knobs, fuel pump housings • Industrial Machinery – Valves, conveying equipment, rollers, springs • Plumbing – Ballcocks, faucet cartridges, impellers, shower heads, faucet underbodies • Electronic – Keytops, switches, buttons • Miscellaneous – A/V cassette components, toiletry articles, zippers, bearings, toy parts 14 The Loctite® Design Guide for Bonding Plastics, Volume 6PDF Image | Design Guide for Bonding Plastics Volume 6 LT-2197

PDF Search Title:

Design Guide for Bonding Plastics Volume 6 LT-2197Original File Name Searched:

henkel-loctite-design-guide-plastic-bonding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |