PDF Publication Title:

Text from PDF Page: 014

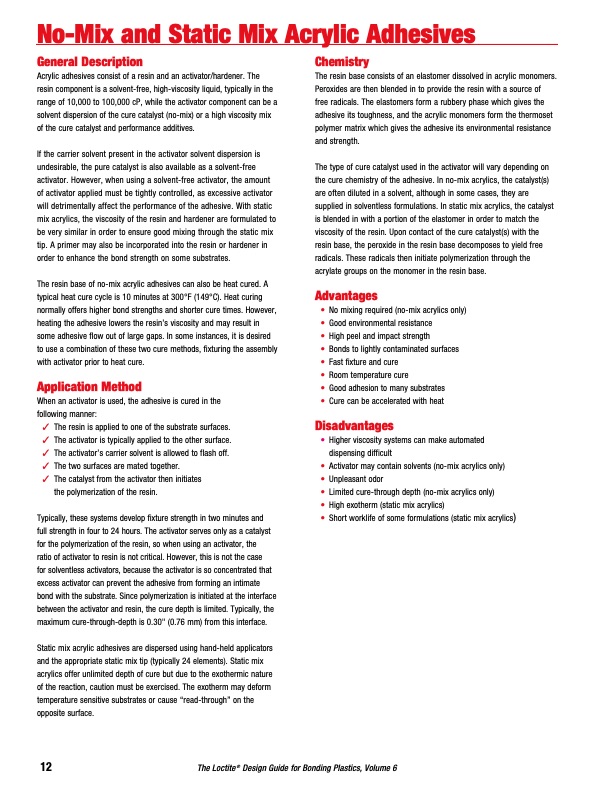

No-Mix and Static Mix Acrylic Adhesives General Description Acrylic adhesives consist of a resin and an activator/hardener. The resin component is a solvent-free, high-viscosity liquid, typically in the range of 10,000 to 100,000 cP, while the activator component can be a solvent dispersion of the cure catalyst (no-mix) or a high viscosity mix of the cure catalyst and performance additives. If the carrier solvent present in the activator solvent dispersion is undesirable, the pure catalyst is also available as a solvent-free activator. However, when using a solvent-free activator, the amount of activator applied must be tightly controlled, as excessive activator will detrimentally affect the performance of the adhesive. With static mix acrylics, the viscosity of the resin and hardener are formulated to be very similar in order to ensure good mixing through the static mix tip. A primer may also be incorporated into the resin or hardener in order to enhance the bond strength on some substrates. The resin base of no-mix acrylic adhesives can also be heat cured. A typical heat cure cycle is 10 minutes at 300°F (149°C). Heat curing normally offers higher bond strengths and shorter cure times. However, heating the adhesive lowers the resin’s viscosity and may result in some adhesive flow out of large gaps. In some instances, it is desired to use a combination of these two cure methods, fixturing the assembly with activator prior to heat cure. Application Method When an activator is used, the adhesive is cured in the following manner: 3 The resin is applied to one of the substrate surfaces. 3 The activator is typically applied to the other surface. 3 The activator’s carrier solvent is allowed to flash off. 3 The two surfaces are mated together. 3 The catalyst from the activator then initiates the polymerization of the resin. Typically, these systems develop fixture strength in two minutes and full strength in four to 24 hours. The activator serves only as a catalyst for the polymerization of the resin, so when using an activator, the ratio of activator to resin is not critical. However, this is not the case for solventless activators, because the activator is so concentrated that excess activator can prevent the adhesive from forming an intimate bond with the substrate. Since polymerization is initiated at the interface between the activator and resin, the cure depth is limited. Typically, the maximum cure-through-depth is 0.30" (0.76 mm) from this interface. Static mix acrylic adhesives are dispersed using hand-held applicators and the appropriate static mix tip (typically 24 elements). Static mix acrylics offer unlimited depth of cure but due to the exothermic nature of the reaction, caution must be exercised. The exotherm may deform temperature sensitive substrates or cause “read-through” on the opposite surface. Chemistry The resin base consists of an elastomer dissolved in acrylic monomers. Peroxides are then blended in to provide the resin with a source of free radicals. The elastomers form a rubbery phase which gives the adhesive its toughness, and the acrylic monomers form the thermoset polymer matrix which gives the adhesive its environmental resistance and strength. The type of cure catalyst used in the activator will vary depending on the cure chemistry of the adhesive. In no-mix acrylics, the catalyst(s) are often diluted in a solvent, although in some cases, they are supplied in solventless formulations. In static mix acrylics, the catalyst is blended in with a portion of the elastomer in order to match the viscosity of the resin. Upon contact of the cure catalyst(s) with the resin base, the peroxide in the resin base decomposes to yield free radicals. These radicals then initiate polymerization through the acrylate groups on the monomer in the resin base. Advantages • No mixing required (no-mix acrylics only) • Good environmental resistance • High peel and impact strength • Bonds to lightly contaminated surfaces • Fast fixture and cure • Room temperature cure • Good adhesion to many substrates • Cure can be accelerated with heat Disadvantages • Higher viscosity systems can make automated dispensing difficult • Activator may contain solvents (no-mix acrylics only) • Unpleasant odor • Limited cure-through depth (no-mix acrylics only) • High exotherm (static mix acrylics) • Short worklife of some formulations (static mix acrylics) 12 The Loctite® Design Guide for Bonding Plastics, Volume 6PDF Image | Design Guide for Bonding Plastics Volume 6 LT-2197

PDF Search Title:

Design Guide for Bonding Plastics Volume 6 LT-2197Original File Name Searched:

henkel-loctite-design-guide-plastic-bonding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |