PDF Publication Title:

Text from PDF Page: 010

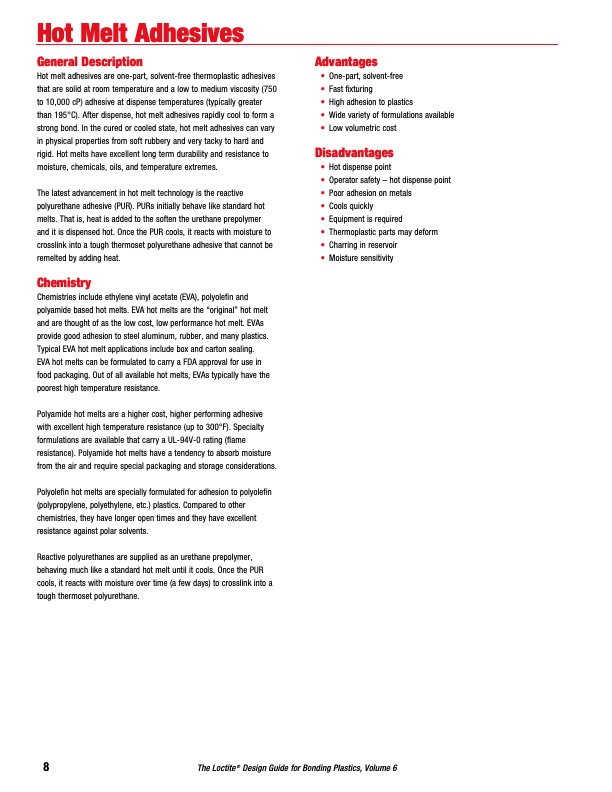

Hot Melt Adhesives General Description Hot melt adhesives are one-part, solvent-free thermoplastic adhesives that are solid at room temperature and a low to medium viscosity (750 to 10,000 cP) adhesive at dispense temperatures (typically greater than 195°C). After dispense, hot melt adhesives rapidly cool to form a strong bond. In the cured or cooled state, hot melt adhesives can vary in physical properties from soft rubbery and very tacky to hard and rigid. Hot melts have excellent long term durability and resistance to moisture, chemicals, oils, and temperature extremes. The latest advancement in hot melt technology is the reactive polyurethane adhesive (PUR). PURs initially behave like standard hot melts. That is, heat is added to the soften the urethane prepolymer and it is dispensed hot. Once the PUR cools, it reacts with moisture to crosslink into a tough thermoset polyurethane adhesive that cannot be remelted by adding heat. Chemistry Chemistries include ethylene vinyl acetate (EVA), polyolefin and polyamide based hot melts. EVA hot melts are the “original” hot melt and are thought of as the low cost, low performance hot melt. EVAs provide good adhesion to steel aluminum, rubber, and many plastics. Typical EVA hot melt applications include box and carton sealing. EVA hot melts can be formulated to carry a FDA approval for use in food packaging. Out of all available hot melts, EVAs typically have the poorest high temperature resistance. Polyamide hot melts are a higher cost, higher performing adhesive with excellent high temperature resistance (up to 300°F). Specialty formulations are available that carry a UL-94V-0 rating (flame resistance). Polyamide hot melts have a tendency to absorb moisture from the air and require special packaging and storage considerations. Polyolefin hot melts are specially formulated for adhesion to polyolefin (polypropylene, polyethylene, etc.) plastics. Compared to other chemistries, they have longer open times and they have excellent resistance against polar solvents. Reactive polyurethanes are supplied as an urethane prepolymer, behaving much like a standard hot melt until it cools. Once the PUR cools, it reacts with moisture over time (a few days) to crosslink into a tough thermoset polyurethane. Advantages • One-part, solvent-free • Fast fixturing • High adhesion to plastics • Wide variety of formulations available • Low volumetric cost Disadvantages • Hot dispense point • Operator safety – hot dispense point • Poor adhesion on metals • Cools quickly • Equipment is required • Thermoplastic parts may deform • Charring in reservoir • Moisture sensitivity 8 The Loctite® Design Guide for Bonding Plastics, Volume 6PDF Image | Design Guide for Bonding Plastics Volume 6 LT-2197

PDF Search Title:

Design Guide for Bonding Plastics Volume 6 LT-2197Original File Name Searched:

henkel-loctite-design-guide-plastic-bonding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |