PDF Publication Title:

Text from PDF Page: 007

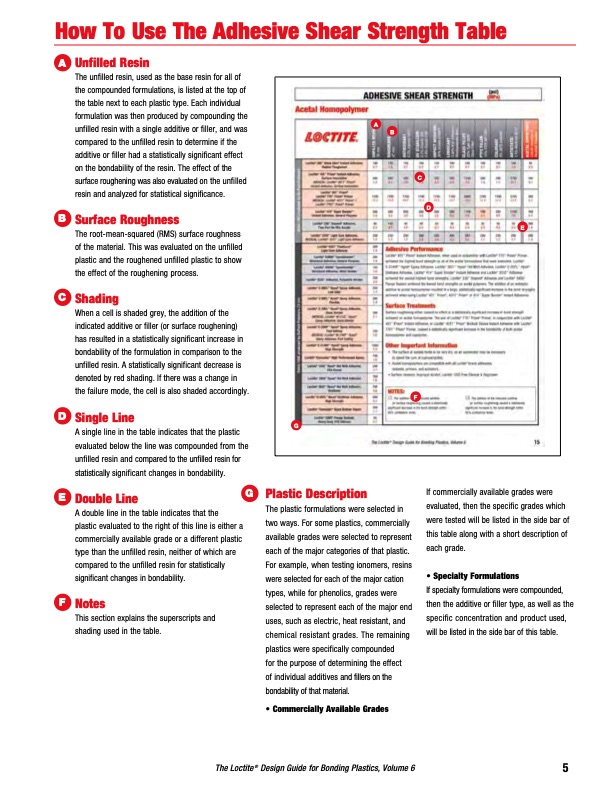

How To Use The Adhesive Shear Strength Table A Unfilled Resin The unfilled resin, used as the base resin for all of the compounded formulations, is listed at the top of the table next to each plastic type. Each individual formulation was then produced by compounding the unfilled resin with a single additive or filler, and was compared to the unfilled resin to determine if the additive or filler had a statistically significant effect on the bondability of the resin. The effect of the surface roughening was also evaluated on the unfilled resin and analyzed for statistical significance. B Surface Roughness The root-mean-squared (RMS) surface roughness of the material. This was evaluated on the unfilled plastic and the roughened unfilled plastic to show the effect of the roughening process. C Shading When a cell is shaded grey, the addition of the indicated additive or filler (or surface roughening) has resulted in a statistically significant increase in bondability of the formulation in comparison to the unfilled resin. A statistically significant decrease is denoted by red shading. If there was a change in the failure mode, the cell is also shaded accordingly. D Single Line A single line in the table indicates that the plastic evaluated below the line was compounded from the unfilled resin and compared to the unfilled resin for statistically significant changes in bondability. G G A B F C D E Plastic Description The plastic formulations were selected in two ways. For some plastics, commercially available grades were selected to represent each of the major categories of that plastic. For example, when testing ionomers, resins were selected for each of the major cation types, while for phenolics, grades were selected to represent each of the major end uses, such as electric, heat resistant, and chemical resistant grades. The remaining plastics were specifically compounded for the purpose of determining the effect of individual additives and fillers on the bondability of that material. • Commercially Available Grades If commercially available grades were evaluated, then the specific grades which were tested will be listed in the side bar of this table along with a short description of each grade. • Specialty Formulations If specialty formulations were compounded, then the additive or filler type, as well as the specific concentration and product used, will be listed in the side bar of this table. E Double Line A double line in the table indicates that the plastic evaluated to the right of this line is either a commercially available grade or a different plastic type than the unfilled resin, neither of which are compared to the unfilled resin for statistically significant changes in bondability. F Notes This section explains the superscripts and shading used in the table. The Loctite® Design Guide for Bonding Plastics, Volume 6 5PDF Image | Design Guide for Bonding Plastics Volume 6 LT-2197

PDF Search Title:

Design Guide for Bonding Plastics Volume 6 LT-2197Original File Name Searched:

henkel-loctite-design-guide-plastic-bonding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |