PDF Publication Title:

Text from PDF Page: 006

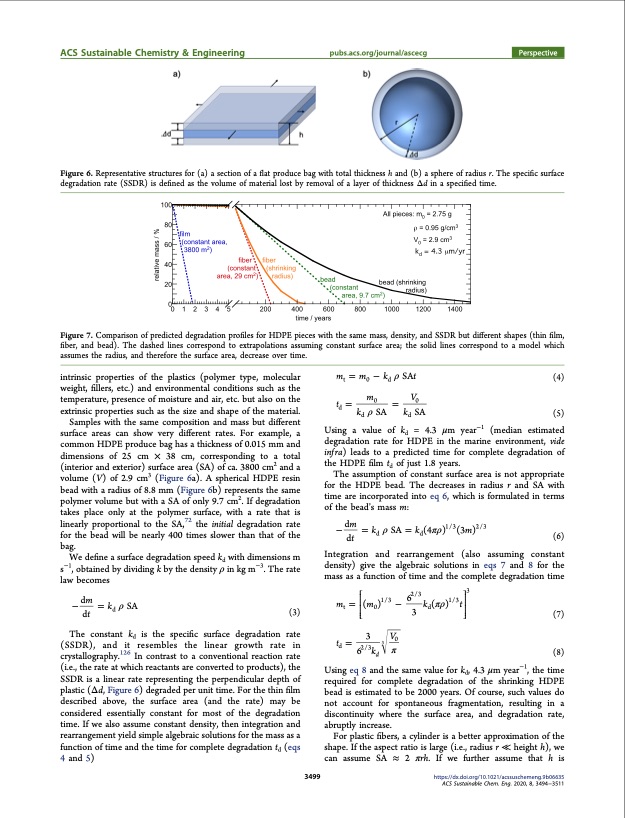

ACS Sustainable Chemistry & Engineering pubs.acs.org/journal/ascecg Perspective Figure 6. Representative structures for (a) a section of a flat produce bag with total thickness h and (b) a sphere of radius r. The specific surface degradation rate (SSDR) is defined as the volume of material lost by removal of a layer of thickness Δd in a specified time. Figure 7. Comparison of predicted degradation profiles for HDPE pieces with the same mass, density, and SSDR but different shapes (thin film, fiber, and bead). The dashed lines correspond to extrapolations assuming constant surface area; the solid lines correspond to a model which assumes the radius, and therefore the surface area, decrease over time. intrinsic properties of the plastics (polymer type, molecular weight, fillers, etc.) and environmental conditions such as the temperature, presence of moisture and air, etc. but also on the extrinsic properties such as the size and shape of the material. Samples with the same composition and mass but different surface areas can show very different rates. For example, a common HDPE produce bag has a thickness of 0.015 mm and dimensions of 25 cm × 38 cm, corresponding to a total (interior and exterior) surface area (SA) of ca. 3800 cm2 and a volume (V) of 2.9 cm3 (Figure 6a). A spherical HDPE resin bead with a radius of 8.8 mm (Figure 6b) represents the same polymer volume but with a SA of only 9.7 cm2. If degradation takes place only at the polymer surface, with a rate that is linearly proportional to the SA,72 the initial degradation rate for the bead will be nearly 400 times slower than that of the bag. We define a surface degradation speed kd with dimensions m s−1, obtained by dividing k by the density ρ in kg m−3. The rate law becomes mt =m0 −kd ρSAt (4) (5) dm − =kdρSA (3) 1/3 Ñ 6 kd π (8) Using eq 8 and the same value for kd, 4.3 μm year−1, the time required for complete degradation of the shrinking HDPE bead is estimated to be 2000 years. Of course, such values do not account for spontaneous fragmentation, resulting in a discontinuity where the surface area, and degradation rate, abruptly increase. For plastic fibers, a cylinder is a better approximation of the shape. If the aspect ratio is large (i.e., radius r ≪ height h), we can assume SA ≈ 2 πrh. If we further assume that h is https://dx.doi.org/10.1021/acssuschemeng.9b06635 dt The constant kd is the specific surface degradation rate (7) (SSDR), and it resembles the linear growth rate in crystallography.126 In contrast to a conventional reaction rate (i.e., the rate at which reactants are converted to products), the SSDR is a linear rate representing the perpendicular depth of plastic (Δd, Figure 6) degraded per unit time. For the thin film described above, the surface area (and the rate) may be considered essentially constant for most of the degradation time. If we also assume constant density, then integration and rearrangement yield simple algebraic solutions for the mass as a function of time and the time for complete degradation td (eqs 4 and 5) td= 2/3 0 3 3499 mV td= 0 = 0 kd ρ SA kd SA Using a value of k = 4.3 μm year−1 (median estimated d degradation rate for HDPE in the marine environment, vide infra) leads to a predicted time for complete degradation of the HDPE film td of just 1.8 years. The assumption of constant surface area is not appropriate for the HDPE bead. The decreases in radius r and SA with time are incorporated into eq 6, which is formulated in terms of the bead’s mass m: dm −dt =kd ρSA=kd(4πρ) (3m) Integration and rearrangement (also assuming constant density) give the algebraic solutions in eqs 7 and 8 for the mass as a function of time and the complete degradation time Ä É3 ÅÑ Å 2/3 Ñ Å6Ñ Å 1/3 mt = ÅÇ(m0) − 3 kd(πρ) tÑÖ 3V 1/3 2/3 ACS Sustainable Chem. Eng. 2020, 8, 3494−3511 (6)PDF Image | Degradation Rates of Plastics in the Environment

PDF Search Title:

Degradation Rates of Plastics in the EnvironmentOriginal File Name Searched:

acssuschemeng-9b06635.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |