PDF Publication Title:

Text from PDF Page: 001

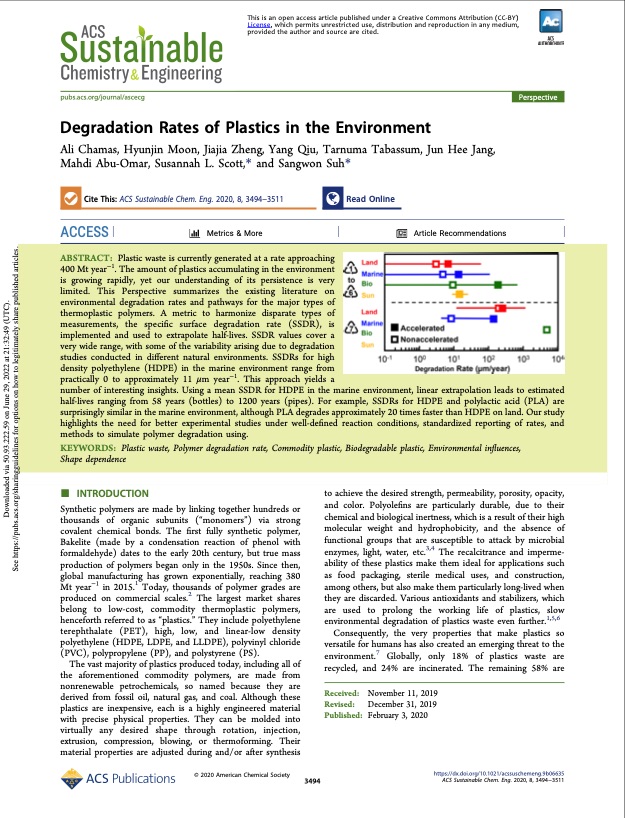

pubs.acs.org/journal/ascecg This is an open access article published under a Creative Commons Attribution (CC-BY) License, which permits unrestricted use, distribution and reproduction in any medium, provided the author and source are cited. Degradation Rates of Plastics in the Environment Ali Chamas, Hyunjin Moon, Jiajia Zheng, Yang Qiu, Tarnuma Tabassum, Jun Hee Jang, Mahdi Abu-Omar, Susannah L. Scott,* and Sangwon Suh* Cite This: ACS Sustainable Chem. Eng. 2020, 8, 3494−3511 ACCESS Metrics & More Read Online Perspective Article Recommendations ABSTRACT: Plastic waste is currently generated at a rate approaching 400 Mt year−1. The amount of plastics accumulating in the environment is growing rapidly, yet our understanding of its persistence is very limited. This Perspective summarizes the existing literature on environmental degradation rates and pathways for the major types of thermoplastic polymers. A metric to harmonize disparate types of measurements, the specific surface degradation rate (SSDR), is implemented and used to extrapolate half-lives. SSDR values cover a very wide range, with some of the variability arising due to degradation studies conducted in different natural environments. SSDRs for high density polyethylene (HDPE) in the marine environment range from practically 0 to approximately 11 μm year−1. This approach yields a number of interesting insights. Using a mean SSDR for HDPE in the marine environment, linear extrapolation leads to estimated half-lives ranging from 58 years (bottles) to 1200 years (pipes). For example, SSDRs for HDPE and polylactic acid (PLA) are surprisingly similar in the marine environment, although PLA degrades approximately 20 times faster than HDPE on land. Our study highlights the need for better experimental studies under well-defined reaction conditions, standardized reporting of rates, and methods to simulate polymer degradation using. KEYWORDS: Plastic waste, Polymer degradation rate, Commodity plastic, Biodegradable plastic, Environmental influences, Shape dependence ■ INTRODUCTION Synthetic polymers are made by linking together hundreds or thousands of organic subunits (“monomers”) via strong covalent chemical bonds. The first fully synthetic polymer, Bakelite (made by a condensation reaction of phenol with formaldehyde) dates to the early 20th century, but true mass production of polymers began only in the 1950s. Since then, global manufacturing has grown exponentially, reaching 380 Mt year−1 in 2015.1 Today, thousands of polymer grades are produced on commercial scales.2 The largest market shares belong to low-cost, commodity thermoplastic polymers, henceforth referred to as “plastics.” They include polyethylene terephthalate (PET), high, low, and linear-low density polyethylene (HDPE, LDPE, and LLDPE), polyvinyl chloride (PVC), polypropylene (PP), and polystyrene (PS). The vast majority of plastics produced today, including all of the aforementioned commodity polymers, are made from nonrenewable petrochemicals, so named because they are derived from fossil oil, natural gas, and coal. Although these plastics are inexpensive, each is a highly engineered material with precise physical properties. They can be molded into virtually any desired shape through rotation, injection, extrusion, compression, blowing, or thermoforming. Their material properties are adjusted during and/or after synthesis to achieve the desired strength, permeability, porosity, opacity, and color. Polyolefins are particularly durable, due to their chemical and biological inertness, which is a result of their high molecular weight and hydrophobicity, and the absence of functional groups that are susceptible to attack by microbial enzymes, light, water, etc.3,4 The recalcitrance and imperme- ability of these plastics make them ideal for applications such as food packaging, sterile medical uses, and construction, among others, but also make them particularly long-lived when they are discarded. Various antioxidants and stabilizers, which are used to prolong the working life of plastics, slow environmental degradation of plastics waste even further.1,5,6 Consequently, the very properties that make plastics so versatile for humans has also created an emerging threat to the environment.7 Globally, only 18% of plastics waste are recycled, and 24% are incinerated. The remaining 58% are https://dx.doi.org/10.1021/acssuschemeng.9b06635 © 2020 American Chemical Society 3494 ACS Sustainable Chem. Eng. 2020, 8, 3494−3511 November 11, 2019 December 31, 2019 Received: Revised: Published: February 3, 2020 Downloaded via 50.93.222.59 on June 29, 2022 at 21:32:49 (UTC). See https://pubs.acs.org/sharingguidelines for options on how to legitimately share published articles.PDF Image | Degradation Rates of Plastics in the Environment

PDF Search Title:

Degradation Rates of Plastics in the EnvironmentOriginal File Name Searched:

acssuschemeng-9b06635.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |