PDF Publication Title:

Text from PDF Page: 004

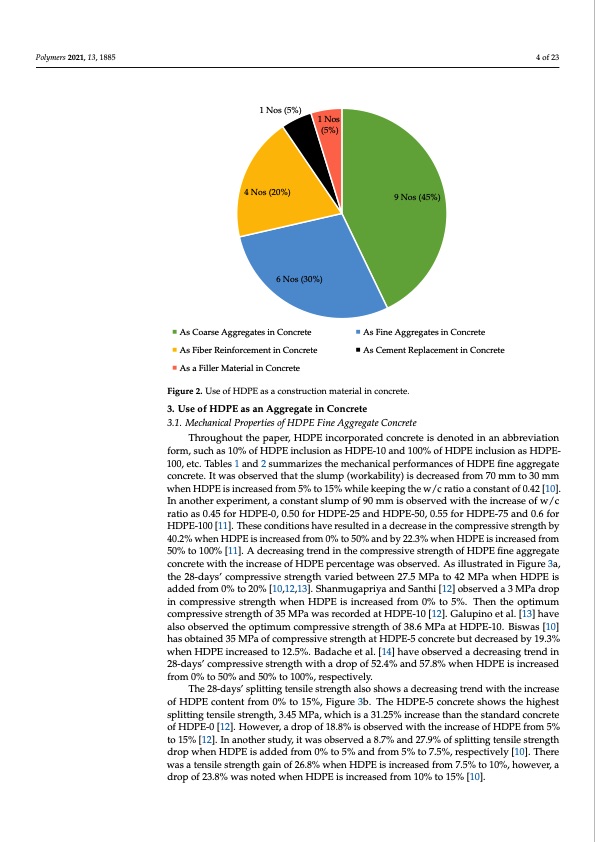

Polymers 2021, 13, 1885 2. Significance of the Review HDPE is the third most applied plastic type in construction preceded by PE and PET. However, a little research is reported in concrete incorporated with HDPE as a construc- tion material, Figure 2. Moreover, there is no systematic review which was conducted by discussing existing research findings of HDPE concrete. Hence, this comprehensive re- 4 of 23 view will provide the clear insight and in-depth analysis of the existing HDPE concrete performance, prevailing research gaps and future research improvements required. 1 Nos (5%) 1 Nos (5%) 4 Nos (20%) 6 Nos (30%) As Coarse Aggregates in Concrete As Fiber Reinforcement in Concrete As a Filler Material in Concrete 9 Nos (45%) As Fine Aggregates in Concrete As Cement Replacement in Concrete Figure 2. Use of HDPE as a construction material in concrete. Figure 2. Use of HDPE as a construction material in concrete. 3. Use of HDPE as an Aggregate in Concrete 3. Use of HDPE as an Aggregate in Concrete 3.1. Mechanical Properties of HDPE Fine Aggregate Concrete 3.1. Mechanical Properties of HDPE Fine Aggregate Concrete Throughout the paper, HDPE incorporated concrete is denoted in an abbreviation Throughout the paper, HDPE incorporated concrete is denoted in an abbreviation form, such as 10% of HDPE inclusion as HDPE-10 and 100% of HDPE inclusion as HDPE- form, such as 10% of HDPE inclusion as HDPE-10 and 100% of HDPE inclusion as HDPE- 100, etc. Tables 1 and 2 summarizes the mechanical performances of HDPE fine aggregate 100, etc. Table 1 and Table 2 summarizes the mechanical performances of HDPE fine ag- concrete. It was observed that the slump (workability) is decreased from 70 mm to 30 mm gregate concrete. It was observed that the slump (workability) is decreased from 70 mm when HDPE is increased from 5% to 15% while keeping the w/c ratio a constant of 0.42 [10]. In another experiment, a constant slump of 90 mm is observed with the increase of w/c ratio as 0.45 for HDPE-0, 0.50 for HDPE-25 and HDPE-50, 0.55 for HDPE-75 and 0.6 for HDPE-100 [11]. These conditions have resulted in a decrease in the compressive strength by 40.2% when HDPE is increased from 0% to 50% and by 22.3% when HDPE is increased from 50% to 100% [11]. A decreasing trend in the compressive strength of HDPE fine aggregate concrete with the increase of HDPE percentage was observed. As illustrated in Figure 3a, the 28-days’ compressive strength varied between 27.5 MPa to 42 MPa when HDPE is added from 0% to 20% [10,12,13]. Shanmugapriya and Santhi [12] observed a 3 MPa drop in compressive strength when HDPE is increased from 0% to 5%. Then the optimum compressive strength of 35 MPa was recorded at HDPE-10 [12]. Galupino et al. [13] have also observed the optimum compressive strength of 38.6 MPa at HDPE-10. Biswas [10] has obtained 35 MPa of compressive strength at HDPE-5 concrete but decreased by 19.3% when HDPE increased to 12.5%. Badache et al. [14] have observed a decreasing trend in 28-days’ compressive strength with a drop of 52.4% and 57.8% when HDPE is increased from 0% to 50% and 50% to 100%, respectively. The 28-days’ splitting tensile strength also shows a decreasing trend with the increase of HDPE content from 0% to 15%, Figure 3b. The HDPE-5 concrete shows the highest splitting tensile strength, 3.45 MPa, which is a 31.25% increase than the standard concrete of HDPE-0 [12]. However, a drop of 18.8% is observed with the increase of HDPE from 5% to 15% [12]. In another study, it was observed a 8.7% and 27.9% of splitting tensile strength drop when HDPE is added from 0% to 5% and from 5% to 7.5%, respectively [10]. There was a tensile strength gain of 26.8% when HDPE is increased from 7.5% to 10%, however, a drop of 23.8% was noted when HDPE is increased from 10% to 15% [10].PDF Image | Concrete Incorporated with Recycled High-Density Polyethylene HDPE

PDF Search Title:

Concrete Incorporated with Recycled High-Density Polyethylene HDPEOriginal File Name Searched:

polymers-13-01885.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |