PDF Publication Title:

Text from PDF Page: 002

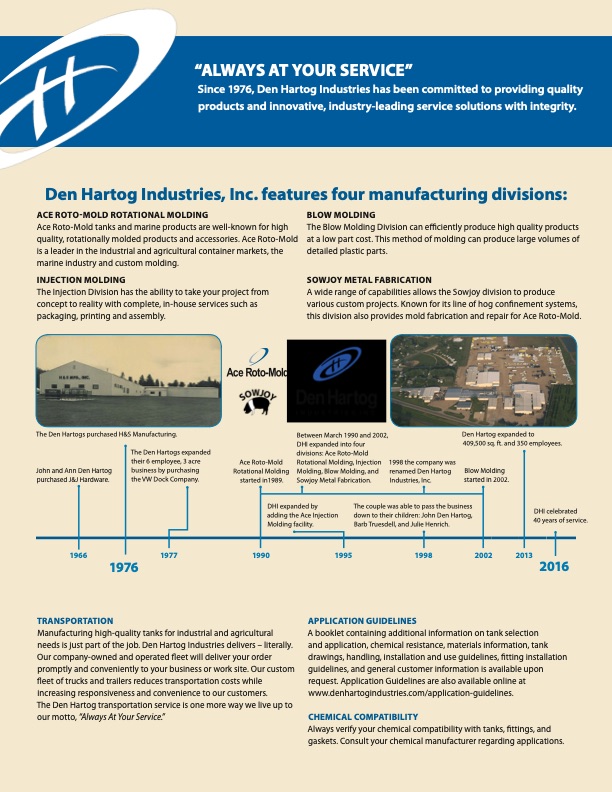

“ALWAYS AT YOUR SERVICE” Since 1976, Den Hartog Industries has been committed to providing quality products and innovative, industry-leading service solutions with integrity. Den Hartog Industries, Inc. features four manufacturing divisions: ACE ROTO-MOLD ROTATIONAL MOLDING Ace Roto-Mold tanks and marine products are well-known for high quality, rotationally molded products and accessories. Ace Roto-Mold is a leader in the industrial and agricultural container markets, the marine industry and custom molding. INJECTION MOLDING The Injection Division has the ability to take your project from concept to reality with complete, in-house services such as packaging, printing and assembly. BLOW MOLDING The Blow Molding Division can efficiently produce high quality products at a low part cost. This method of molding can produce large volumes of detailed plastic parts. SOWJOY METAL FABRICATION A wide range of capabilities allows the Sowjoy division to produce various custom projects. Known for its line of hog confinement systems, this division also provides mold fabrication and repair for Ace Roto-Mold. The Den Hartogs purchased H&S Manufacturing. Between March 1990 and 2002, DHI expanded into four divisions: Ace Roto-Mold Rotational Molding, Injection Molding, Blow Molding, and Sowjoy Metal Fabrication. Den Hartog expanded to 409,500 sq. ft. and 350 employees. John and Ann Den Hartog purchased J&J Hardware. The Den Hartogs expanded their 6 employee, 3 acre business by purchasing the VW Dock Company. Ace Roto-Mold Rotational Molding started in1989. 1998 the company was renamed Den Hartog Industries, Inc. Blow Molding started in 2002. DHI expanded by The couple was able to pass the business adding the Ace Injection down to their children: John Den Hartog, Molding facility. Barb Truesdell, and Julie Henrich. DHI celebrated 40 years of service. 2013 2016 1966 1976 TRANSPORTATION 1977 1990 1995 1998 2002 APPLICATION GUIDELINES Manufacturing high-quality tanks for industrial and agricultural needs is just part of the job. Den Hartog Industries delivers – literally. Our company-owned and operated fleet will deliver your order promptly and conveniently to your business or work site. Our custom fleet of trucks and trailers reduces transportation costs while increasing responsiveness and convenience to our customers. The Den Hartog transportation service is one more way we live up to our motto, “Always At Your Service.” A booklet containing additional information on tank selection and application, chemical resistance, materials information, tank drawings, handling, installation and use guidelines, fitting installation guidelines, and general customer information is available upon request. Application Guidelines are also available online at www.denhartogindustries.com/application-guidelines. CHEMICAL COMPATIBILITY Always verify your chemical compatibility with tanks, fittings, and gaskets. Consult your chemical manufacturer regarding applications.PDF Image | Blow Molding Injection Molding Rotational

PDF Search Title:

Blow Molding Injection Molding RotationalOriginal File Name Searched:

DHI_Catalog_Reprint_19_FINAL.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |