PDF Publication Title:

Text from PDF Page: 014

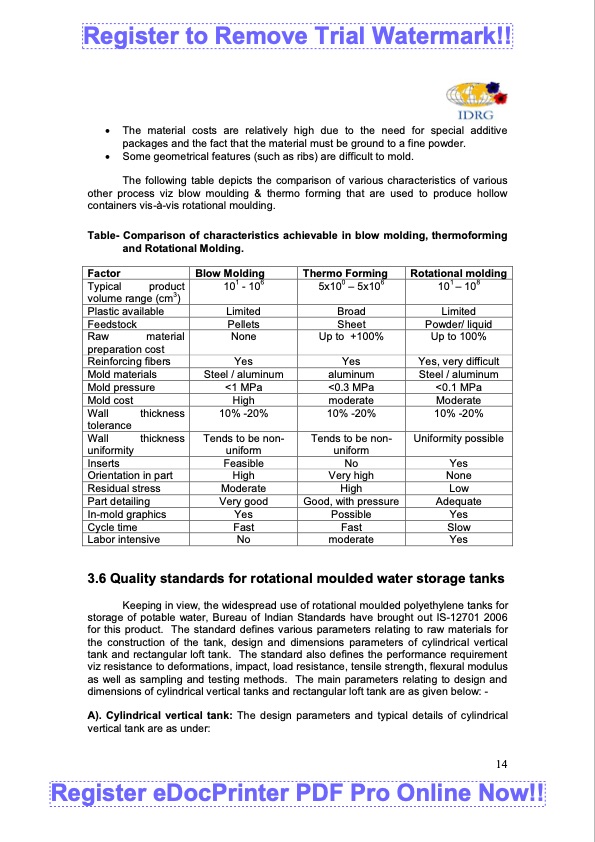

Register to Remove Trial Watermark!! The material costs are relatively high due to the need for special additive packages and the fact that the material must be ground to a fine powder. Some geometrical features (such as ribs) are difficult to mold. The following table depicts the comparison of various characteristics of various other process viz blow moulding & thermo forming that are used to produce hollow containers vis-à-vis rotational moulding. Table- Comparison of characteristics achievable in blow molding, thermoforming and Rotational Molding. Factor Typical product volume range (cm3) Plastic available Feedstock Raw material preparation cost Reinforcing fibers Mold materials Mold pressure Mold cost Blow Molding 101 - 106 Limited Pellets None Yes Steel / aluminum <1 MPa High 10% -20% Tends to be non- uniform Feasible High Moderate Very good Yes Fast No Thermo Forming 5x100 – 5x106 Broad Sheet Up to +100% Yes aluminum <0.3 MPa moderate 10% -20% Tends to be non- uniform No Very high High Good, with pressure Possible Fast moderate Rotational molding 101 – 108 Limited Powder/ liquid Up to 100% Yes, very difficult Steel / aluminum <0.1 MPa Moderate 10% -20% Uniformity possible Yes None Low Adequate Yes Slow Yes Wall tolerance Wall uniformity Inserts Orientation in part Residual stress Part detailing In-mold graphics Cycle time Labor intensive thickness thickness 3.6 Quality standards for rotational moulded water storage tanks Keeping in view, the widespread use of rotational moulded polyethylene tanks for storage of potable water, Bureau of Indian Standards have brought out IS-12701 2006 for this product. The standard defines various parameters relating to raw materials for the construction of the tank, design and dimensions parameters of cylindrical vertical tank and rectangular loft tank. The standard also defines the performance requirement viz resistance to deformations, impact, load resistance, tensile strength, flexural modulus as well as sampling and testing methods. The main parameters relating to design and dimensions of cylindrical vertical tanks and rectangular loft tank are as given below: - A). Cylindrical vertical tank: The design parameters and typical details of cylindrical vertical tank are as under: 14 Register eDocPrinter PDF Pro Online Now!!PDF Image | ANALYSIS OF ROTO-MOULDED PLASTIC CONTAINERS

PDF Search Title:

ANALYSIS OF ROTO-MOULDED PLASTIC CONTAINERSOriginal File Name Searched:

Construction-PART-3.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |