PDF Publication Title:

Text from PDF Page: 004

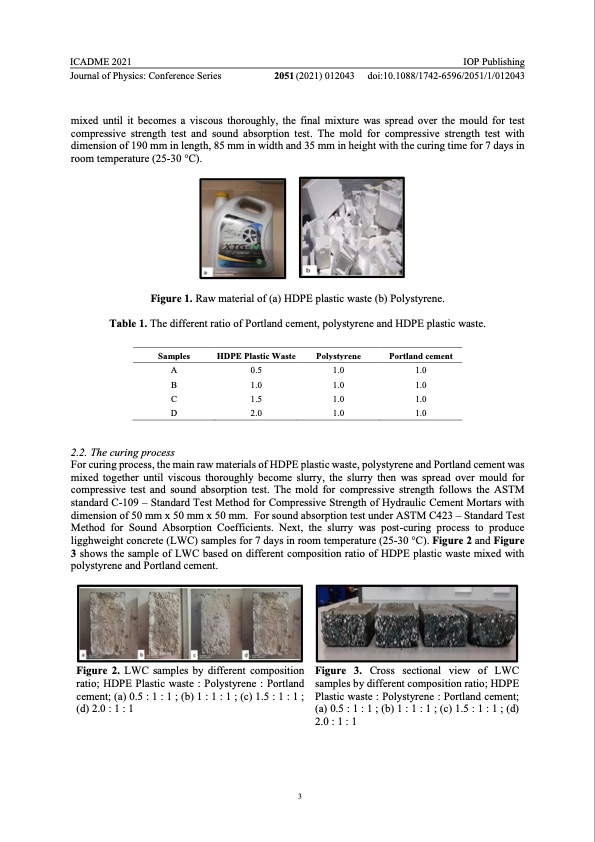

ICADME 2021 IOP Publishing Journal of Physics: Conference Series 2051 (2021) 012043 doi:10.1088/1742-6596/2051/1/012043 mixed until it becomes a viscous thoroughly, the final mixture was spread over the mould for test compressive strength test and sound absorption test. The mold for compressive strength test with dimension of 190 mm in length, 85 mm in width and 35 mm in height with the curing time for 7 days in room temperature (25-30 °C). Figure 1. Raw material of (a) HDPE plastic waste (b) Polystyrene. Table 1. The different ratio of Portland cement, polystyrene and HDPE plastic waste. Samples A B C D 2.2. The curing process HDPE Plastic Waste Polystyrene 0.5 1.0 1.0 1.0 1.5 1.0 2.0 1.0 Portland cement 1.0 1.0 1.0 1.0 For curing process, the main raw materials of HDPE plastic waste, polystyrene and Portland cement was mixed together until viscous thoroughly become slurry, the slurry then was spread over mould for compressive test and sound absorption test. The mold for compressive strength follows the ASTM standard C-109 – Standard Test Method for Compressive Strength of Hydraulic Cement Mortars with dimension of 50 mm x 50 mm x 50 mm. For sound absorption test under ASTM C423 – Standard Test Method for Sound Absorption Coefficients. Next, the slurry was post-curing process to produce ligghweight concrete (LWC) samples for 7 days in room temperature (25-30 °C). Figure 2 and Figure 3 shows the sample of LWC based on different composition ratio of HDPE plastic waste mixed with polystyrene and Portland cement. Figure 2. LWC samples by different composition Figure 3. Cross sectional view of LWC ratio; HDPE Plastic waste : Polystyrene : Portland samples by different composition ratio; HDPE cement;(a)0.5:1:1;(b)1:1:1;(c)1.5:1:1; Plasticwaste:Polystyrene:Portlandcement; (d) 2.0 : 1 : 1 (a) 0.5 : 1 : 1 ; (b) 1 : 1 : 1 ; (c) 1.5 : 1 : 1 ; (d) 2.0 : 1 : 1 3PDF Image | analysis of HDPE plastic

PDF Search Title:

analysis of HDPE plasticOriginal File Name Searched:

Manaf_2021_Phys3A_2051_012043.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |