PDF Publication Title:

Text from PDF Page: 007

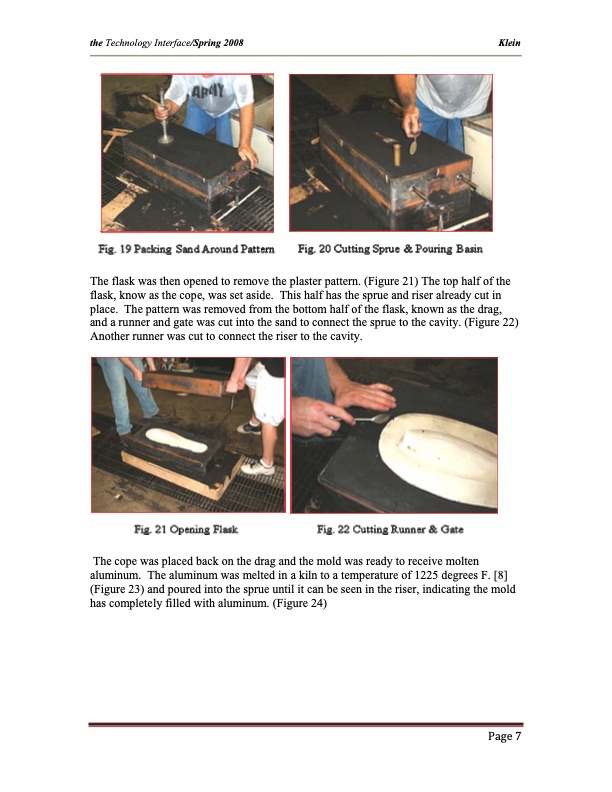

the Technology Interface/Spring 2008 Klein The flask was then opened to remove the plaster pattern. (Figure 21) The top half of the flask, know as the cope, was set aside. This half has the sprue and riser already cut in place. The pattern was removed from the bottom half of the flask, known as the drag, and a runner and gate was cut into the sand to connect the sprue to the cavity. (Figure 22) Another runner was cut to connect the riser to the cavity. The cope was placed back on the drag and the mold was ready to receive molten aluminum. The aluminum was melted in a kiln to a temperature of 1225 degrees F. [8] (Figure 23) and poured into the sprue until it can be seen in the riser, indicating the mold has completely filled with aluminum. (Figure 24) Page 7PDF Image | 12 mil Reinforced Polyethylene

PDF Search Title:

12 mil Reinforced PolyethyleneOriginal File Name Searched:

Klein-Rotational Molded Plastics.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |